25 Jun A Quick Guide to Innovative Die-Cut Packaging Solutions

When it comes to the success of your company and the products you sell, packaging matters! 72% of Americans say that packaging design influences their decision to purchase a product, and 67% agree that the materials used in the packaging affect their decision.

For this reason, it’s essential that your packaging incorporates unique elements to stand out to customers. In fact, “64% of consumers will share a product on social media if it has unique and creative packaging,” which can enhance brand recognition.

One process that can elevate your printed products is die-cutting. Read on to learn more about this option, which can help you create consistent, precise, creative, and unique designs!

Whether you’re new to the concept or looking to enhance your understanding, this guide will cover three essentials of die-cutting

1. What is Die-Cutting?

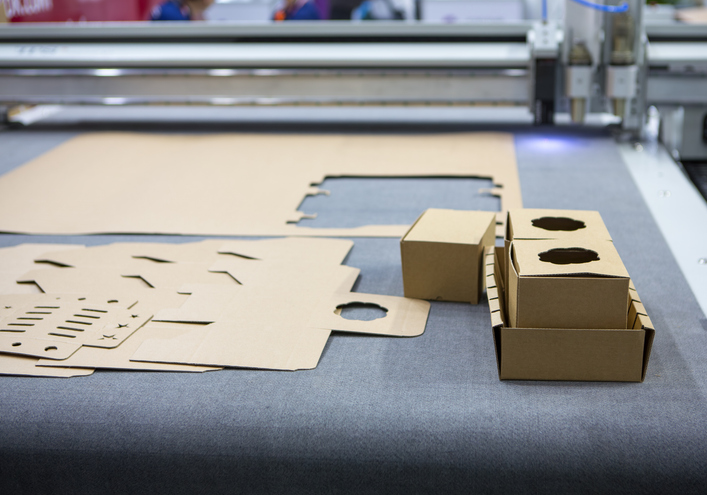

Die-cutting is a process commonly used in printing and packaging products across various industries.

At its simplest, die-cutting refers to using a die (a sharp-edged object resembling a cookie cutter in a specific shape) to cut out different designs on a raw material. Due to its precision and accuracy, this method is popular for creating product packaging.

You can set a die-cut machine to cut specific dimensions each time, quickly producing a large quantity. This precision and efficiency make it an excellent choice for producing commercial materials, such as labels or packaging, that look consistent and neat.

2. Types of Die-Cut Processes

There are multiple methods of die-cutting, each providing different outcomes depending on your project’s needs. Some common types are:

- Blanking: Slices material from the outside edge to create flat, uniform pieces.

- Forming: Uses a curved surface to wrap your design around cylindrical parts of a package.

- Drawing: Feeds the material through the machine to be cut at a specific length, ideal for thin or long products.

- Broaching: Uses multiple rows of “teeth” to cut through thicker materials that traditional steel dies cannot.

- Coining: Punches tiny holes in the material by applying pressure and force.

In addition to these common types, there are also two primary die-cutting services:

- Flatbed/Steel Rule Die-Cutting: This method uses custom-made dies to create shapes on a flatbed-style press. It is best for thicker materials or smaller production volumes.

- Rotary Die-Cutting: This method uses cylindrical dies, ideal for producing larger quantities of products with flexible materials and ensuring high accuracy.

3. Tips for Creating Die-Cut Labels or Packages

Incorporating die-cutting into your packaging or labels is a great practice with many options and benefits. Here are a few tips to keep in mind when creating your designs:

- Include a bleed area that extends your artwork by at least 1/16″ past the label’s boundaries to prevent unintentional white spaces.

- Add an outline overlay mimicking the cut shape to your digital design file to ensure the edges of your design aren’t cut off or obscured after printing.

- Avoid acute angles or sharp corners in your design, as these can tear when the matrix is removed after die-cutting.

- Get creative! Experiment with new shapes and visuals to keep your packaging and labels visually appealing to customers.

Contact our company today for assistance creating high-quality die-cut printed products or for any of your other printing needs!